JOHNAN provides consistent services and assistance from product development and prototyping to mass production, including small-lot multi-product production.

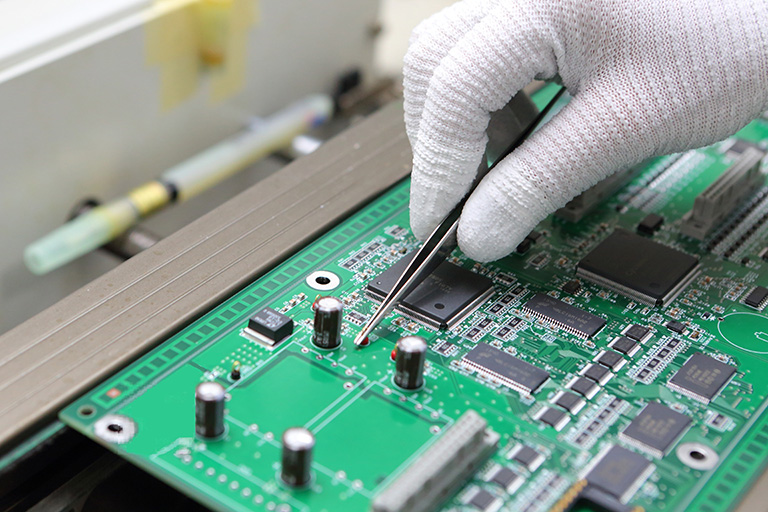

JOHNAN offers consistent services and assistance from product development and prototyping to mass production. Providing various proposals to solve challenges relating to PCB mounting, we support high-quality manufacturing. We also flexibly respond to changes in mass production systems due to sudden fluctuations in production.

1. Features and strengths

(1) Providing a one-stop service

Providing consistent services from substrate design to production and inspection, we help reduce management man-hours and manufacturing costs. We have abundant experience in production support for fabless companies.

(2)Passion for manufacturing

We help ensure high-quality manufacturing with careful consideration of productivity and quality. Our IPC-A-610 certified specialists and certified ESD coordinators respond to your requests.

(3) Consistent services and assistance from product development and prototyping to mass production

We help solve various challenges in PCB mounting from development and prototyping to mass production. With consideration of the improvement of productivity and quality, we offer proposals for substrate design, material procurement, manufacturing methods, and many other matters.

* IPC-A-610 is an inspection standard for the acceptability of electronic assemblies (quality standard for the production of electronic equipment). An ESD coordinator is a static electricity controller certified based on quality standards for manufacturing electronic equipment.

2. Products and service

We meet a wide range of needs relating to the manufacturing of electronic components and equipment or PCB mounting, from development and prototyping to mass production.

Applicable board

Ceramic PCB, aluminum PCB , Flexible pattern circuit, multi-layered PCB, L size PCB , paper phenol PCB, etc.

Type of solder

Pb-free solder (with Ag) Pb-free solder (without Ag)

Applicable board

- ■SMT mounting (surface mounting technology)

-

- [accuracy]chip0402, lead spacing: 0.3mm, adjoining pitch: 0.1mm.

- [IC package types] BGA, SOP, QFP, LED, QFN, etc.

- [Corresponding size] Maximum size: 360mm×410mm Plate thickness: 0.5mm~1.6mm (MAX:5.0mm).

- ■Chip-on-Board mounting

-

- [Mountable chip thickness]0.2 mm to 10 mm

- [Wire] Gold wire (20 to 38μ), Aluminum wire (100 to 400μ)

- ■Capability for chip mounting/discrete mounting

-

- ・chip0402

- ・chip0603

- ・We have experience of mounting 0603 chips using bonding adhesives and flow soldering.

- ・3D mounting

3. Processes

Providing one-stop solutions from circuit design to finished products.

Circuit design

Parts procurement

Parts processing

PCB mounting

Product assembly

Quality inspection

Packing/Shipment

4. Production base

■domestic

West Japan Business Department-

West Japan Business