Introduction of Functional Film Surface Mount Technology to be beyond your design limits!

Currently, in Semiconductor, PCBA of automotive, industrial, medical, and infrastructure market, various needs of manufacturing and design are expanding. JOHNAN is developing"Surface Mount Technology on Functional Film", to make product design restriction flexible, and create additional value on product design.

1. Functinal Film Mount Technology.

The JOHNAN's new technologies means to place/interconnect electrical components on Functional Film. Utilizing the new technology, JOHNAN provides three kinds of services.

- 1. Insert the film in Hot melt Injection.

- 2. Wearable products.

- 3. Stretchable PCB.

Functinal Film Mount Technology.

(Films of PET, PC, Silicon and Urethane)

Conductive Adhesive.

(Types of Epoxy, Silicon, Urethane)

● Insert the film in Hot melt Injection.(JOHNAN In-Mold)

● Wearable products.(JOHNAN Wearable)

● Stretchable Film PCBA.(JOHNAN Stretchable)

2. JOHNAN's challenge.

(1)JOHNAN In-Mold.

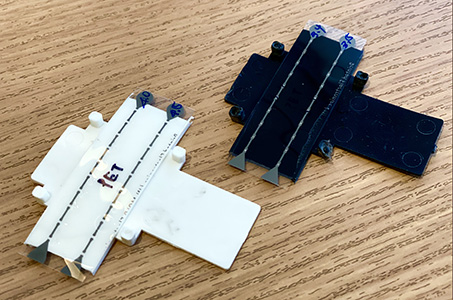

Hot melt injection and film mount technology enables soft and stiff type injection. Flexible Functional film enables to insert molding which are various form shaping parts. JOHNAN In-Mold service enables to mount SMD on thin flex film, and bring your product design and mechanical design highly flexible. For example, to insert flexible film into water-proof injection molding makes much less material and less process, then make it water proof protection.

(2)JOHNAN Wearable.

Wearable devices mount technology is a process technologies that enable circuit patterning and component mounting on Poly Urethane and Silicon film, which is stretchable, and PET and PC film, which is flexible. It contributes to mount on curving surface.

(3)Mount technology on Stretchable film.

Stretchable mount technology is to assemble SMD on stretchable functional film and sheet. JOHNAN is developing quite unique assembly technology of functional film. From now on, JOHNAN intends to contribute textile and medical application with the technologies. Currently JOHNAN is looking for partners who collaborates the development with us. (INQUIRYHere)

You can have a web interviewContact Us.

3. Report of experiment.

JOHNAN is aggressively developing hot melt injection type of mounted film insert molding, a sort of In-Mold Electronics, and stretchable film mount technology. Here, we introduce one of the trial results.

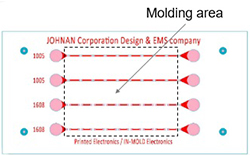

(1)Hot melt type In-Mold Electronics.

(2)Stretchable Film PCBA.(JOHNAN Stretchable)

Directly mount and interconnect to conductive circuit pattern on functional film which is able to stretch. When stretching, the form and shape more flexible than conventional polyimide FPC. In the video, you can watch them closely. You can take a look that the mounted components are attached on flexible and elastic stretching film.

4. Our direction.(Collaboration and Partnership)

JOHNAN aggressively reinforces services with functional film mount technology. In each categories of Film circuit, SMT, Injection molding, JOHNAN is going to develop new process and technologies. Encountering new partnership, which is design and R&D sectors, JOHNAN intends to accelerate the development. In JOHNAN, we have lots of expertise who experienced manufacturing process deeply, and provide value added proposals. Please feel free to inquire us.

● Film Circuit.

(Base material)

PET, Polycarbonate

Poly Urethane, silicon

Thermal plastic sheet.

(Patterning)

Flexibility and Stretch-ability Ag Ink.

Stretchable Ag ink.

JOHNAN

● Injection molding.

(Molding material and process)

Soft type: Hot Melt Injection.

Hard type: Hard hot melt.

PP resin and primer treatment Forming.

● Wearable

Protection for Parts nd interconnection.

● PCBA service and consultation

| Conductive adhesive : | Low temp and short time curing.(reflow duration time 10 to 30min) PET (150 ℃), PC (120 ℃), Silicon (200 ℃), Polyurethane (120 ℃) Improvement of Interconnection strength up. |

|---|---|

| Process : | Part tentative attachment, Potting and Stiffener. |

| Adhesive : | Binder of Epoxy, Silicon, Urethane. |

| Dispense technology : |